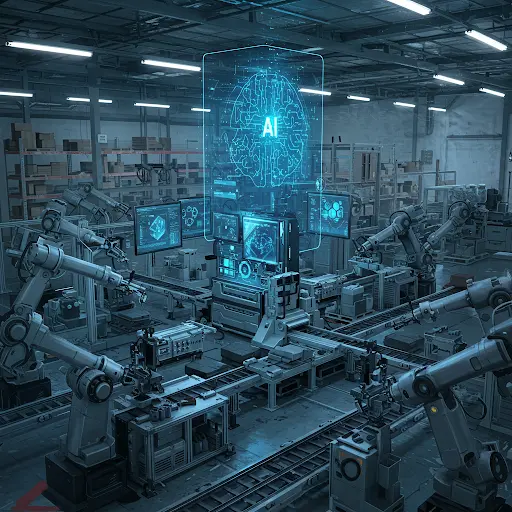

What is AI automation in manufacturing ?

AI automation is rapidly redefining manufacturing across the globe. It has a broad spectrum—from optimizing production processes to enabling entirely new business models—while its worldwide adoption reflects a shift toward smarter, more resilient manufacturing ecosystems.

Scope of AI Automation in Manufacturing

- Predictive Maintenance:

AI-driven sensors and analytics monitor machine health in real time, predicting failures before they happen. This can minimize downtime, extend equipment life, and reduce maintenance costs. - Quality Assurance and Control:

Using computer vision and machine learning, AI systems can inspect products on the production line for defects and anomalies. It enhances product quality, lowers waste levels, and reduces rework. - Process Optimization:

AI can analyze production data to optimize workflows, adjust process parameters, and streamline manufacturing operations. This can improve efficiency, conserve resources, and increase overall productivity. - Supply Chain and Inventory Management:

AI can forecast demand, optimize stock levels, and orchestrate logistics to ensure smooth supply chain operations. It can lead to cost savings, minimize delays, and reduce excess inventory. - Robotic Process Automation and Cobots:

Collaborative robots (cobots) and AI-enhanced machinery can handle repetitive, precise, or hazardous tasks alongside human workers. It enhances workplace safety, increases production flexibility, and supports human workers in value-added tasks. - Digital Twins and Simulation:

AI can create digital replicas of manufacturing processes or entire facilities, enabling simulation and optimization without physical trial and error thereby accelerating process innovation and minimizing risk during changes or scaling of operations.

Worldwide Adoption of AI Automation

North America and Europe

- Current trends show emphasis on Industry 4.0, where legacy systems are upgraded with digital capabilities. There is a strong collaboration between technology vendors, startups, and established manufacturers that leads to the integration of advanced analytics, IoT, and AI.

- Government incentives, research investments, and a focus on increasing operational efficiency are the drivers of adopting automation.

- Challenges in adoption can include high initial capital costs, challenges in integrating old systems, and the need for upskilling the workforce.

Asia-Pacific

- Countries like China, Japan, and South Korea are at the forefront with initiatives like “smart factories” and advanced robotics. Robust government backing and rapidly evolving industrial policies accelerate AI adoption.

- The sheer scale of manufacturing and strong competitiveness in global markets are the drivers of adopting automation

- Challenges in adoption can include managing integration into large-scale environments and ensuring robust cybersecurity across interconnected systems.

Emerging Markets (Latin America, Africa, and the Middle East)

- These regions are gradually adopting AI to stay competitive on a global scale. They often start with pilot projects focused on specific pain points such as quality control or supply chain efficiency.

- Key driver is the need to modernize and improve production despite limited legacy infrastructure.

- Barriers in adoption include Infrastructure challenges and the need for significant investments in both technology and training.

Companies transforming manufacturing with automation:

Rockwell Automation:

Rockwell Automation drives manufacturing innovation by providing integrated control systems, sensors, and industrial IoT platforms that automate production processes. Their advanced automation solutions—such as PLCs, HMIs, and real-time analytics software—enable predictive maintenance, streamline operations, and optimize workflows. As a result, manufacturers benefit from improved efficiency, reduced downtime, and higher product quality.

ABB:

ABB is driving manufacturing automation by integrating advanced robotics, industrial software, and electrification solutions. Their systems automate repetitive tasks, monitor and control processes in real time, and enable predictive maintenance through IoT connectivity. This leads to reduced downtime, optimized energy usage, and enhanced productivity, helping manufacturers increase efficiency and product quality.

Siemens:

Siemens accelerates manufacturing automation by integrating advanced hardware and digital solutions. They provide programmable logic controllers, robotics, sensors, and control systems that automate production processes. Through digital platforms like MindSphere, Siemens enables real-time data analytics, predictive maintenance, and process optimization, leading to enhanced quality control, reduced downtime, and improved operational efficiency for manufacturers.

Texas Instruments (TI):

TI boosts manufacturing automation by providing advanced semiconductor solutions—including analog and digital integrated circuits, embedded processors, and connectivity chips—that power smart industrial systems. TI’s technologies enable real-time monitoring, precise process control, and efficient power management in machinery and robotics. This results in improved operational efficiency, reduced downtime, and enhanced quality control for manufacturers.

LeewayHertz:

LeewayHertz drives manufacturing automation by developing custom digital solutions that integrate blockchain, IoT, and cloud technologies. Their platforms enable real-time monitoring, secure data exchange, and enhanced supply chain traceability. This results in streamlined operations, automated asset tracking, and improved process efficiency for manufacturers.

Schneider Electric:

Schneider Electric automates manufacturing by offering integrated digital solutions that combine energy management, process control, and IoT connectivity through their Ecostruxure platform. This integration enables real-time monitoring, predictive maintenance, and optimized energy usage, leading to reduced downtime, enhanced productivity, and more sustainable manufacturing operations.

Explore AI automation services here

Conclusion

In conclusion, AI automation in manufacturing is not just about replacing older manual processes—it’s about creating a seamlessly integrated, digitally-augmented production environment. Manufacturers around the world are harnessing AI to achieve significant gains in efficiency, quality, and competitive advantage, even as they navigate challenges such as high upfront costs, integration issues, and workforce adaptation.